Top AI Hacks That Will Transform Your Manufacturing Business

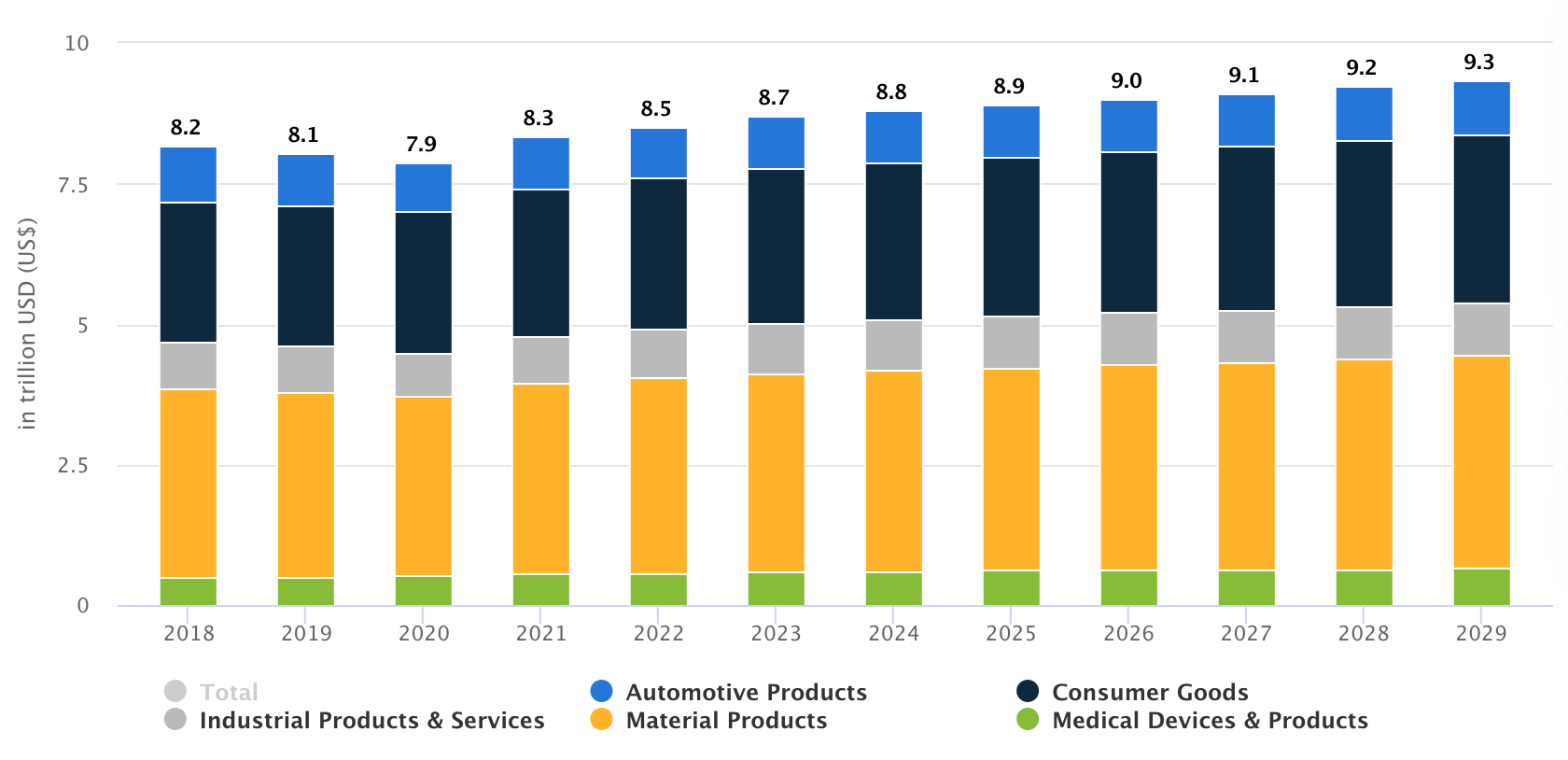

Manufacturing is one of the big four that keeps the global economy going, right up there with services, agriculture, and tech. And get this—Statista predicts the manufacturing market will hit a massive $8.8 trillion by the end of 2024.

The value of the manufacturing market in 2024, source Statista.

In the US alone, the number of people involved in manufacturing is estimated at 12.7 million, not to mention countries like China and India, where the population is 10 times larger than the population of the United States.

The manufacturing sector covers all sorts of physical goods. This includes turning raw materials or semi-finished products into finished items, plus constructing, placing, and repairing industrial machinery and equipment.

Manufacturing is closely intertwined with a bunch of different domains, like food and drinks, textiles, chemicals, metalworking, and electronics. It’s a big deal that touches on a lot of areas.

With such a dense and complex nature, it’s no surprise that manufacturing requires high technology support, mainly artificial intelligence (AI) and machine learning, to refine expenses, reduce waste, and improve production process efficiency.

This way, today, we’ll go over seven major AI hacks your manufacturing company can employ right away and see immediate results.

Why Modern Manufacturing Can’t Do Without High Technologies

Before we plunge into the specific AI hacks in manufacturing, let’s take a step back and see how AI influences the field and why it’s becoming a must-have instrument in modern production circumstances.

The modern manufacturing environment increasingly suffers from the pressure to release more with less. Relying on classic scenarios—manual processes and human decision-making—doesn’t cut it anymore.

AI actually has all the powers to help plants and factories rearrange pretty much every part of their operations. For example, industrial companies using AI can get over all main problems, such as excessive waste, human errors, and irrational resource distribution.

What Artificial Intelligence Can Do in Manufacturing

Hack #1: Predictive Upkeep

Unplanned downtime is one of the most irritating points for any manufacturer, and it always seems to happen at the worst times.

Thanks to AI, however, it has become possible to fix the machine before it even turns into an issue, which is called predictive maintenance.

By using special sensors to diagnose machines and inspecting incoming data, AI can predict when a machine is about to break down and plan maintenance exactly when it’s needed.

Such an approach visibly cuts down on pricey downtime, keeps the equipment running longer, and helps avoid sudden accidents.

Hack #2: Smart Automation

Automation isn’t new, but AI remakes it with what we call “smart” automation.

AI can regulate more than just simple, duplicative tasks—it memorizes and adapts, making it perfect for running assembly lines or administering inventory.

The magnificence of AI-driven automation is that it’s more adjustable and rational. It lets people dedicate their time to more fine and subtle tasks while computers take over the boring, detail-intensive sides.

Hack #3: Quality Control & Defect Detection

Almost 60% of people surveyed say quality control is the top reason to use artificial intelligence.

With AI-powered vision systems, you can spot flaws and imperfections that human eyes might miss.

Put simply, AI systems scan thousands of products in a split second and catch even the most undersized issues, helping product quality stay consistently high.

Hack #4: Supply Chain Optimization

Though AI can now be used in the end-to-end supply chain across the board, some years ago, supply chain optimization through emerging tech seemed nonsense accompanied by lots of risks and limitations.

Today, AI is able to rank and organize information based on specific filters, quickly interpret and alter processes and operations, recap large sets of data, drag critical insights and coincidences, recognize images, and help recover relevant records.

Hack #5: Production Planning & Scheduling

When it comes to production planning, AI is great at fine-tuning schedules to cut down on downtime and get the most out of every production run.

It takes real-time data from all machines involved in production, workforce availability, and shifts in demand, adjusting production plans on the fly.

In short, this all-around approach means better resource estimates, faster lead times, and smarter resource use. With AI, your production line runs like a well-oiled machine, always performing at its best!

Hack #6: Cobots

Cobots, or collaborative robots, are designed to work right alongside a human group.

Unlike accustomed robots that need to be separated, cobots powered by AI can adapt to assist workers with their chores, whether it’s lifting heavy parts or handling delicate assembly work.

They’re a great AI hack for manufacturers who want to combine the strengths of humans and the intelligence of robots.

Hack #7: Building Something New

Artificial intelligence isn’t just about polishing up what you already do—it’s also a means for experimenting and building entirely new or previously unexplored products or processes.

For example, manufacturers can use predictive modeling to spot trends and guess what customers might want, use rapid prototyping to whip up and test new designs in no time, come up with new product ideas, and employ simulations to see how those products will hold up in different situations.

How to Get Started with AI in Manufacturing

Embedding AI might feel a bit intimidating at first sight, but taking it step by step can make the transition much simpler.

Begin by pinpointing all the areas in your workflow where AI could make a notable effect.

For example, think about using AI for predictive maintenance to keep your machines running properly or improving quality control to catch the tiniest defects.

Once you’ve specified these areas, you can add AI solutions. As you start to see positive effects, you can gradually expand your use of AI across other aspects of your manufacturing processes.

This tactic not only lets you govern the change, but it also gives your crew a chance to adapt to new reforms without feeling confused.

In case you need extra help, you can always team up with an experienced AI vendor or consultant. They’ll help you steer the integration procedure and prove artificial intelligence meshes well with your current systems and workflows.

If you’re on the lookout for premier AI solutions, SCAND has got your back. Our team can show you how to use AI for corporates and create custom applications that will open up hidden opportunities you might not even be aware of.