Supply Chain Optimization: Everything You Need to Know

A fast-growing demand in e-commerce and online services has revealed the necessity for many businesses to reconsider how they manage their supply chains. The rise in product demand, need for greater flexibility, and willingness to provide customer service at a high level made businesses turn to supply chain optimization.

Supply chain optimization allows companies to keep their competitive edge in the market, decreasing supply costs and avoiding fragmented supply chain management. In this article, we explain how supply chain optimization helps companies improve their administration, enhance customer satisfaction, and how to build effective supply chain management systems (SCM).

What Is Supply Chain Optimization?

Supply chain optimization (SCO) is a powerful strategy implemented by many businesses to reduce production and operating expenses as well as improve supply chain overall performance and efficiency.

Businesses opt for SCO when they want to improve their financial results, e.g. balance transportation costs with product demands or when they are undergoing a business merger or acquisition process when two businesses need to align their supply chain workflow with each other.

SCO is a complicated process and usually involves several phases:

- supply chain design – when company structures and administers the supply chain so that it can find the most optimal balance between product manufacturing, storage, and transportation costs;

- supply chain planning – involves detailed planning of material delivery to the point of manufacture and a final product journey to a customer;

- supply chain execution – when a company makes the best use of available assets, effectively controls costs, and manages to timely deliver the right items to its customers.

Solid software solutions significantly facilitate the process of supply chain optimization. That’s why before starting their SCO, many businesses turn to a careful selection of supply chain apps. In many cases, businesses prefer to build their own supply chain software solutions. This allows them to precisely adjust the software to the needs of the company, ensure detailed supply chain analysis, and gain valuable insights on possible improvements as well as effectively scale the software in line with the business development.

Benefits of Supply Chain Optimization

With supply chain optimization businesses can gain better working capacity and enhance their customer satisfaction. An effectively designed SCO process helps businesses to:

- decrease silos – carefully optimized supply chains have improved visibility and better data exchange; as a result, it allows many business partners involved in the supply chain to better track the journeys of products or raw materials, timely address any inventory lacks, better anticipate possible overstock or understock challenges and mitigate the risks;

- lower operational costs – SCO allows businesses to improve their logistics operations, making supply chain workflow precise and providing the possibility to find the lowest cost of transportation, storing, product manufacturing, and other services;

- better address client needs – in the conditions of the on-demand economy when customer expectations are high, companies attempt to provide the best service to retain their buyers; streamlining their supply chains helps companies to satisfy their clients with fast product delivery and quickly handle the issues raised by customers;

- gain competitive advantage in the market – with advanced supply chains businesses focus more on supply chain execution rather than supply chain network design; as a result, companies can make real-time decisions and better plan their future business strategies;

- improve supply chain agility – well-optimized supply chains can better respond to the daily business challenges related to customer high/low goods demands, supply distribution, market fluctuations, and others;

- facilitate many supply chain processes – SCO software helps businesses to simply perform complex tasks in supply chain processes, e.g. supplier onboarding and collaboration, acceleration of lead time, solving customer issues, and others.

The Challenges of Supply Chain Optimization

There are a variety of challenges companies face when opting for SCO. Though, according to the latest SpendEdge presentation, if companies manage to undergo the optimization process successfully, they can reduce company expenses by 10% to 40% and significantly improve their decision-making.

The key SCO problems include location, production, and inventory accuracy. Let’s have a closer look at them and possible solutions.

- Location

It’s essential for a company to consider where to place their production plants, distribution warehouses, and stocking facilities. Many companies place themselves closer to their end-users while building their manufacture nearer to the source of the raw material. For companies it’s essential to correctly analyze the market demands and properly identify where to locate, considering the regulatory norms of the areas they want to launch their branches in.

- Production

Deciding how many items a company needs to produce to satisfy the market demand is one of the most widespread SCO issues today. Besides that, businesses have to consider the quality of the goods they produce. Therefore, companies have to perform a careful market analysis and investigate alternative product costs and market demand. Moreover, they need to make many operational decisions related to workload scheduling, equipment maintenance, product quality estimation, outsourcing of production if needed, and others.

- Inventory accuracy

On average, inventory management costs reach 20-40% of their value. Therefore, for effective work of a supply chain, businesses should accurately track their inventory levels and ensure their timely delivery. For this businesses need effective warehouse management software that could maintain an optimal stock level.

All these issues can be effectively addressed with well-thought-out digital solutions that contain advanced analytic tools, provide high data visibility among departments and business partners, and offer convenient instruments for inventory management.

SCAND Best Practices for Supply Chain Optimization

One of the most effective ways to optimize supply chains is to develop custom supply chain management software based on cloud infrastructure. While custom software development offers tailor-made solutions specific to the needs of a particular business, cloud infrastructure makes it sustainable, simple to scale, easy to access for various business participants, and extremely secure.

SCAND has extensive experience in building robust and effective custom supply chain management solutions, including those that have cloud infrastructure in their core.

Software developers at SCAND have experience working with Amazon AWS, Google Cloud, and Microsoft Azure.

For Google Cloud we use:

- IAM for management of users/roles;

- IAP for management of access to the resources;

- Armor for protecting entry points into the application;

- Google monitoring – for gathering logs from containers (not for all projects);

- Kubernetes engine (RBAC, Container-Optimized OS) for orchestration and autoscaling of containers;

- KMS for management of keys/secrets;

- GSuite for management of Google accounts and MFA;

- Cloud SQL – MySQL/PostgreSQL dependant on project needs;

- VPC Network Peering – private connectivity access VPC networks;

- Firewall rules – management of firewall rules between VPC, based on network tags;

- Service accounts – helps to manage permission for applications/VMs instead of to an individual end-user;

- reCAPTCHA – for blocking automated intrusions;

- Compute Engine for management of single instances;

- Memorystore (Redis) for fast storages;

- Load balancing – for balancing of incoming requests and performing simple protection operations;

- NAT for regulation of access from external systems;

- Container registry for the management of own artifacts;

- Cloud build for performing artifact builds;

- Google Storage – for storing static assets and files;

- Pub/Sub – high-efficiency MQ broker.

For AWS we use:

- AWS IAM for users/roles management;

- AWS EC2: Instances, VPC, Elastic Load Balancing, Security groups, etc.;

- AWS Glacier for archives;

- AWS S3, S3 Glacier – base long-term storage;

- AWS EKS – management of Kubernetes or creating customer Kubernetes cluster on EC2 using EC2 Spot Instances for decreasing cost of the system;

- Elastic Container Registry, Elastic Container Service – working with containers;

- AWS Lambda – implementing service tasks and processing of events initiated by AWS instances;

- AWS SNS – for notification purposes;

- SES, WorkMail for work with emails;

- RDS, DynamoDB, ElastiCache – for storing data;

- AWS Memcached – for caching purposes.

For Azure we use:

- Azure Active Directory – corporate authentication;

- Virtual Machines for management of single instances;

- Kubernetes service – for management of Kubernetes clusters;

- Virtual Networks – for creation of private networks;

- Resource Group – uniting several resources;

- Storage Account, Disk Storage – for data storing;

- Network interface – for controlling of services communication;

- Network security group – for maintaining security rules and traffic control.

Besides that, for additional maintenance, monitoring, and security, SCAND developers use the following tools:

- OSS and Falco for intrusion detection;

- Terraform and Ansible for application and deployment management;

- Jenkins, Bitbucket pipeline for building;

- ELK/Tick/Prometheus and Grafana for monitoring.

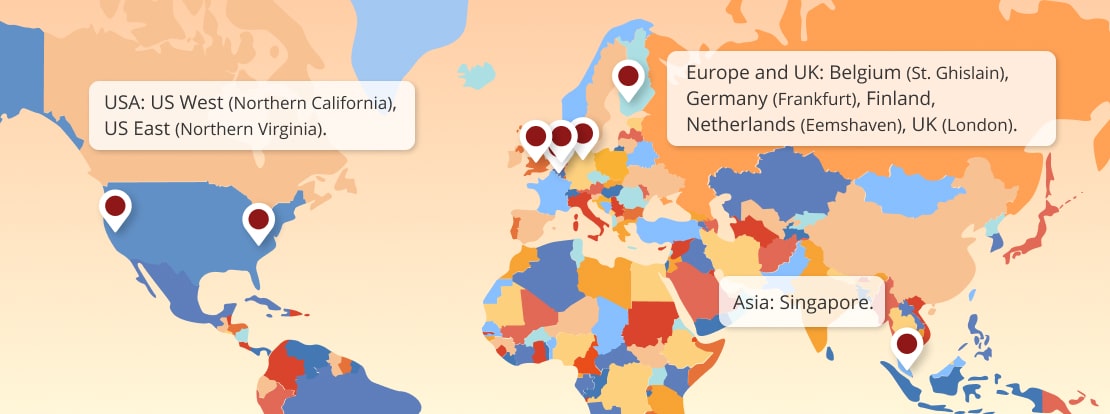

Geo locations are dependent on project interest areas. If interest lies within one geographical area, the production environment should be located either to be accessed fast from different target users’ areas. Or special techniques should be used (like VPC Network Peering) to guarantee fast access between different parts of the environment.

SCAND team uses the most effective locations for placing their production environments around the world, which include:

Conclusion

Supply chain optimization is an effective strategy that allows businesses to remain stable in the market, provide high-quality customer service, and minimize operational costs. Although SCO is rather complex and involves a variety of changes at each supply chain management step, companies manage to significantly reduce their expenses and improve decision-making once the changes are made.

The key elements for effective SCO are well-chosen software and infrastructure. That’s why many businesses prefer to build their own supply chain management software based on cloud services. SCAND company has 20+ of experience in the software development market and has already delivered a wide range of SCM solutions, including order management software, procurement management systems, supply chain enterprise applications, delivery service platforms, field service applications, inventory management systems, and others. For more information review our portfolio.