How to Overcome Supply Chain Disruption Challenges with Technology Implementation

We currently live in a deeply interdependent world economy that coordinates millions of businesses from different areas or countries. For this global system to run as a coherent mechanism, companies must meticulously regulate their activities.

This is the point at which supply chain management services become necessary. They form and uphold a strong network between companies and suppliers to make products and deliver them to customers.

The supply chain, in turn, involves many moving parts, such as organizations, resources, information, and people, all working together in a branched web to balance supply and demand. An important criterion for the success of such a complex system is its resilience.

In the past few years, however, supply chains have been hit by many problems, such as resource shortages, the coronavirus pandemic, and rising fuel and energy prices.

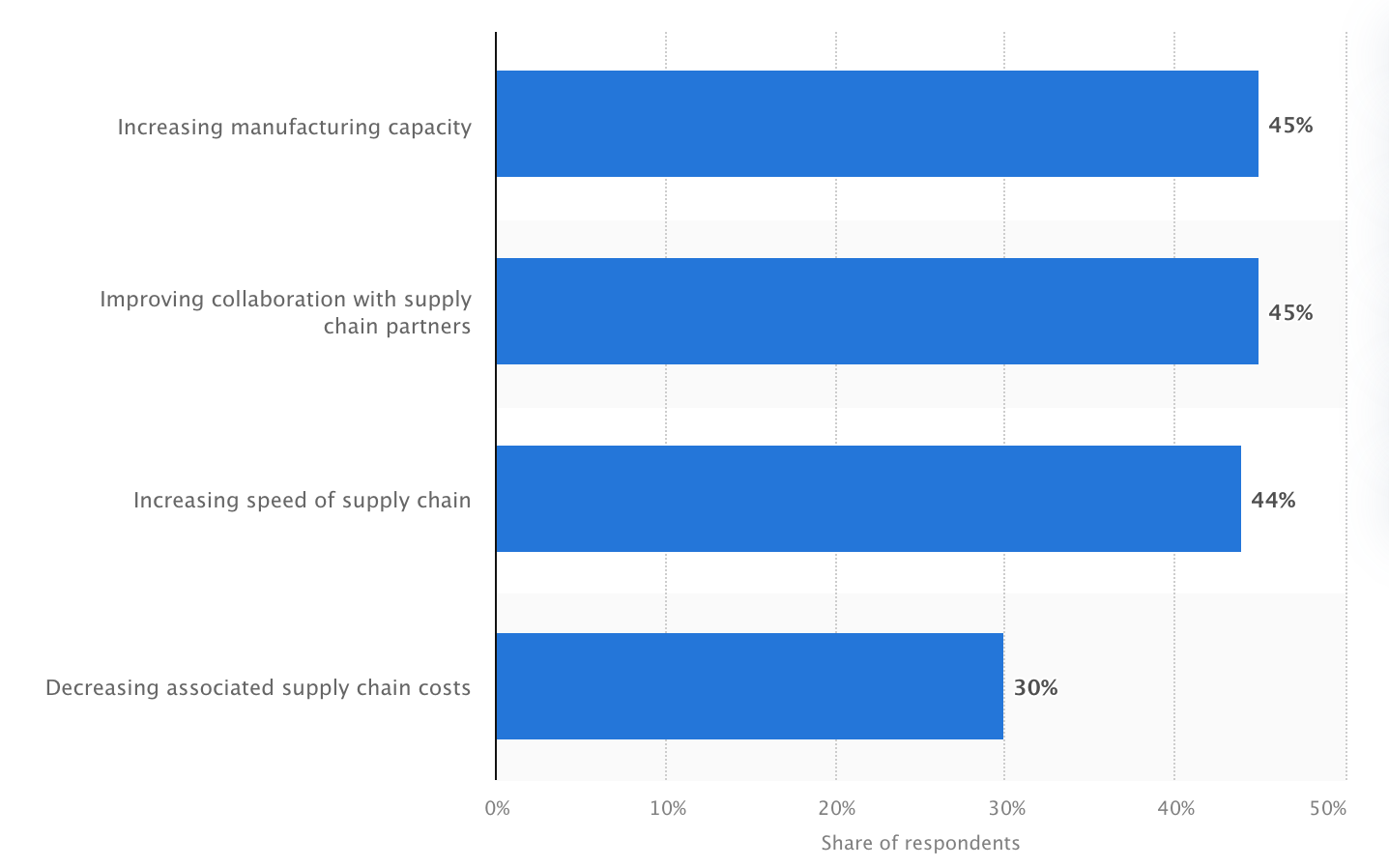

Many businesses have been forced to respond to the new reality and invest in upgrading their supply chains to improve production capabilities, partnerships, and speed.

Main supply chain management improvements companies want to invest in, Statista

Back in 2022, there was a survey among entrepreneurs on what they see as the main driving force of modernization. Nearly 60% of the businesses admitted that they expect technology and robotic process automation to have a major influence on supply chains.

Common Challenges in Supply Chain Management

At times free from disruptions, the international production cycle can work pretty efficiently even without external reinforcement. Yet, when some disorders occur, things look much more negative than one could expect.

Some industries are more vulnerable to sudden disturbances in the supply chain than others. However, even if you think you’re on the safe side, it is important to always be alert to understand what measures are best taken to maintain balance.

Unpredictable Demand

One of the greatest challenges is trying to figure out how much of something individuals will want to buy.

If companies get it wrong, then they end up with too much stock, which is money lost, or too little, which amounts to missed sales and unhappy customers. Demand varies based on infinite reasons—holiday buying patterns, sporadic manias, or even unexpected epidemics.

Trouble Balancing Inventory

Maintaining just the right quantity of goods on hand is no less difficult. Too many goods frozen in inventory cost money to store and tie up capital that could be spent elsewhere. Having too little means running short when customers need it.

Unreliable Suppliers

Suppliers are the pillars of making a supply chain function, but they are not all equal. Poor delivery, inferior quality, or even inadequate communication from their side can cause major setbacks.

And if outside factors are added to all this, such as natural disasters, labor strikes, or political unrest, things can become even worse.

Uneven Logistics

It takes a lot of planning to ship products from factories to warehouses and then to consumers.

Companies, in turn, have to decide on the most reasonable routes for shipping, deal with customs if they’re exporting products, and avoid delays. Waits caused by nasty weather, high traffic, or spikes in fuel prices can throw delivery schedules off.

Poor Visibility

In most supply chains, it’s hard to see what’s happening at each stage. With limited visibility, companies might not hear about problems until it’s too late.

For example, they might not realize that a shipment is falling behind or that the wrong goods were shipped by a supplier. Limited transparency can lead to delays and confusion.

Pressure to Be Sustainable

Today, more and more consumers are thinking about the sources of products and how they are produced.

So companies are under pressure to make their supply chains more environmentally friendly—through less carbon footprint, reduced wastage, and the assurance that suppliers use ethical labor practices.

Technological Solutions to Current Supply Chain Challenges

Working with familiar solutions that have been helping supply chain specialists for years rarely poses challenges.

Working with the latest technology, even if it’s just software development services, however, can be both thrilling and intimidating. There are new applications and the possibility for time and budget savings, higher earnings, and more.

But there can also be uncertainty about the return on investment; user adoption; and the possible reduction, if not elimination, of human employment.

Still, with more inventions in the pipeline, supply chain technology will keep pushing organizations to new primes and potential.

Internet of Things (IoT)

IoT basically refers to an environment where objects are furnished with unique detectors and the capability to transfer data on their state over a network without needing human intervention.

IoT devices play a central role in supply chain optimization. Sensors being embedded in products and equipment allow companies to watch the factual location, temperature, and condition of the goods throughout the entire cycle.

Besides, due to IoT in logistics, companies can immediately respond to urgent issues, refine route planning, and harvest data for predictive maintenance to thwart expensive equipment collapse.

Artificial Intelligence and Machine Learning

Many independent sources claim that the adoption rate of AI and ML is expected to grow in companies working in manufacturing and distribution in 2025 and after. And this is not another hyped but short-lived craze.

Forbes, for example, believes that for modern supply chains, the latest software engines equipped with GenAI, deep learning, and NLP (natural language processing) can process far larger datasets than more premature solutions.

Newer types of AI tools can analyze intricate variables, including MRO inventory and spending data, far more quickly.

Apart from studying and processing data records, they are capable of forecasting customer demand and optimizing all critical nodes within a chain, from inventory management to planning and production scheduling.

Blockchain Technology

When thinking about how best to use blockchain technology in the supply chain, it is necessary to bring back to mind that supply chains are, at their nature, a network of interconnected enterprises.

In that network, each business adds value to a product before it arrives to the end user. This succession of actions is always accompanied by a string of transactions, data, and finances.

Blockchain, in this regard, can provide exceptional clarity and security by offering a permanent record book where each operation or movement of goods is registered and stored so no one can alter or erase it when made.

As a result, all parties can trace products from raw materials to final delivery without the possibility of fraud and counterfeiting.

However, that’s not all. Deloitte, for instance, names far more use cases, such as forecasting risk, refining visibility and traceability for critical product parts, and improving data accuracy.

Besides, blockchain technology can take advantage of other emerging technologies such as the Internet of Things, smart contracts, and artificial intelligence.

Robotics and Automation

Robotics and automation refer to the process of substituting activities previously completed by people with automated devices.

Overall, automation can put in order operations across the whole supply chain, but it’s particularly helpful in warehousing and logistics. Robotics can streamline picking, sorting, and packing, as well as ensure faster and more accurate inventory administration.

Advanced Analytics

Advanced analytics implies the use of autonomous or semi-autonomous examination of data or other logs often using AI to extract deeper insights, make prognoses, or form suggestions.

Advanced analytics involves a variety of techniques, including data and text mining, pattern matching, semantic analysis, sentiment analysis, graph study, multivariate statistics, visualization, forecasting, simulation, and more.

By analyzing data on customer behavior, supplier performance, and inventory levels, businesses can refine processes, improve final output, and make better decisions that go in line with strategic goals.

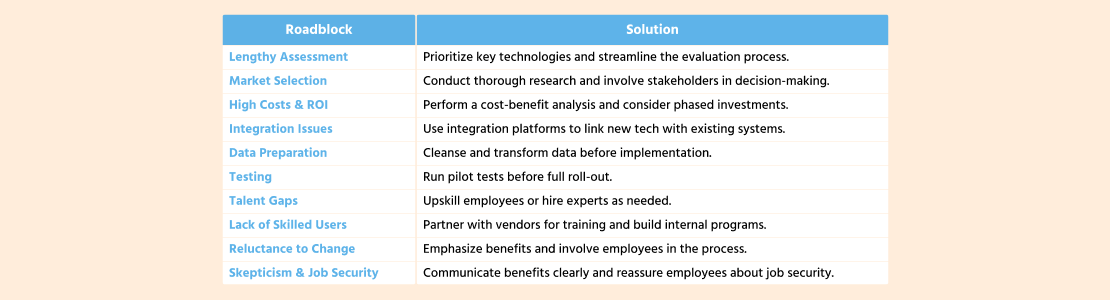

Supply Chain Technology Challenges

Implementing the above or any other type of supply chain technology is not always easy. According to the ASCM report, there are a scope of roadblocks you might struggle with along the way.

First of all, it’s a lengthy process of assessment, which most likely means that you will have to go through each type of technology to understand whether it is appropriate for your company or not.

A Table Examining the Roadblocks and Solutions in Implementing Supply Chain Technology

The evaluation process can also entail probing other options on the market and selecting the one with the most potential. Additionally, technology in general is a substantial financial investment, so ROI must never be overlooked.

Then comes the implementation process. It should involve linking the technology to existing systems and preparing the data that the technology must work with.

It’s also necessary to test the technology before rolling it out to all operations. If there are any talent gaps, you’ll either need to hire new experts with the applicable knowledge or train your existing employees to run the technology.

The best approach, however, is often to do both. With the most advanced solutions, though, there may not be anyone with the skillfulness and proficiency to use it or the knowledge to perform training.

In the end, you’ll need to try things out and learn as you go. People often feel reluctant to change, so it’s important to carefully direct them through it.

Also, they might be skeptical about using new solutions or worried that it could affect their jobs—or even replace them. That’s why helping them feel comfortable and showing them the benefits of the new tool is so meaningful.

Best Practices for Enforcing Technology in Supply Chains

Implementing new technology in a supply chain can make things work faster, but it needs to be done the right way. If businesses rush into it without a plan, it could bring about chaos and tension.

First, it’s important to get everyone involved and on board. People are more inclined to accept new technology when they know why it is being implemented and how it will benefit them.

That’s why companies need to communicate the change ahead of time to all parties, including employees, suppliers, and logistics providers.

When people know how the new tools will make their jobs easier or solve issues they already have, they will be less stressed and more receptive to change.

Next is training. If people aren’t shown how to properly use the technology, they might get frustrated and stick with their old ways of doing things.

To head this off, companies need to offer brief, interactive training, either in the form of workshops, tutorials, or one-on-one sessions. Getting users to feel comfortable and confident goes a long way.

Another useful suggestion is to start small. Instead of installing the technology across the entire supply chain in one go, it’s better to test it on a small scale to start with.

If it concerns new software, you can start with an MVP to test things out. This gradual approach reduces risks and makes the whole process way nicer.

Even once the technology is live, it’s a good practice to regularly check how effectively it’s performing. With monitoring and adjusting, they can stay agile and confirm they’re getting the most out of the technology.

Case Studies of Successful Technology Integration

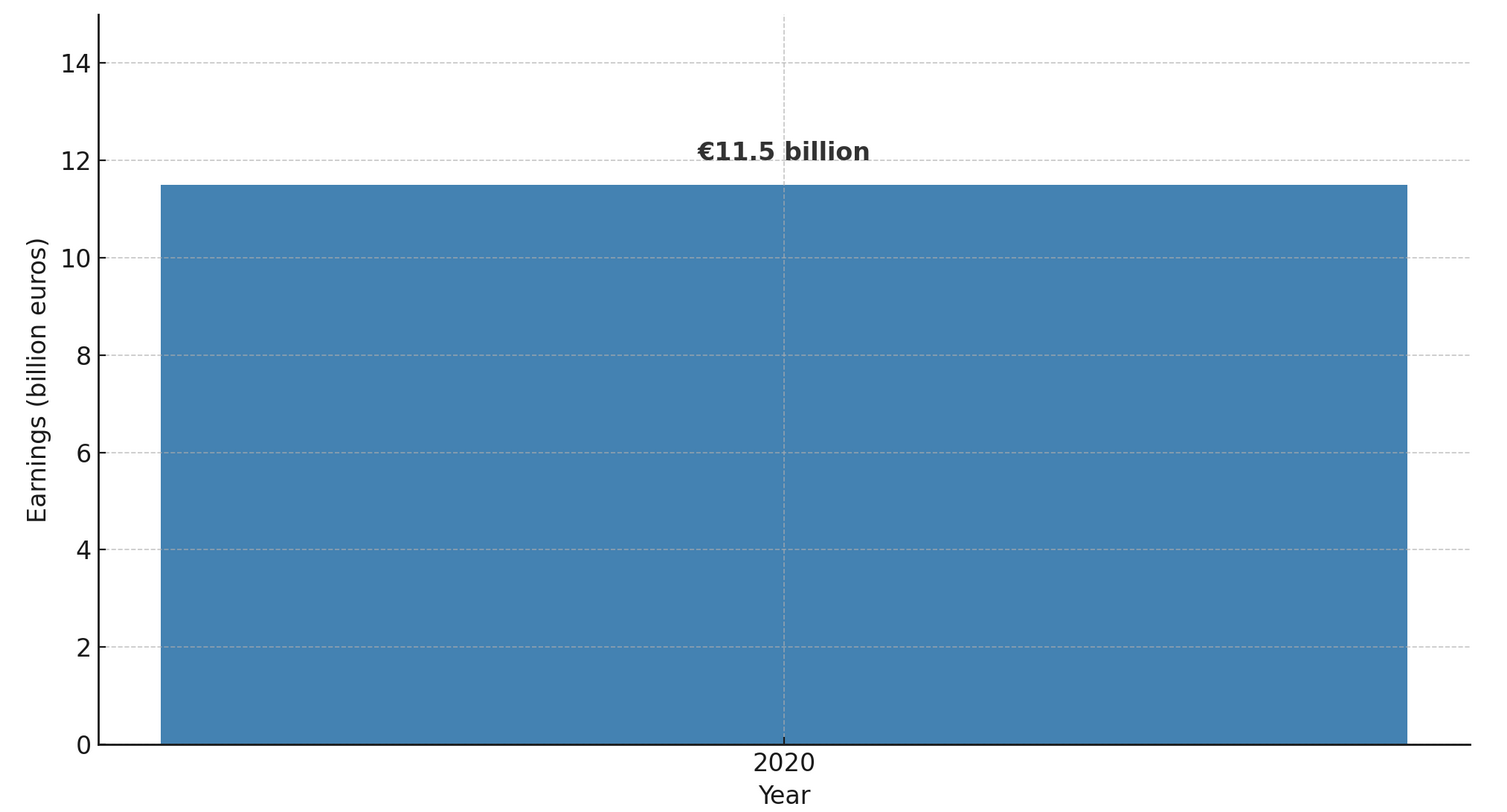

In 2020, SAP became one of the largest global investors in supply chain management software, earning around 11.5 billion euros during this period from its software support activity.

SAP’s Earnings from Supply Chain Management Software Support (2020)

Since then, the supply chain industry has seen hundreds of such examples. Below are some of the most significant ones.

Walmart: Keeping Shelves Stocked with IoT

Walmart is a good example of how technology can move supply chain management with the help of the Internet of Things.

With the help of IoT devices and intelligent sensors, Walmart is now capable of observing its goods in real time, keeping a record of the amount of inventory and the exact position of goods in its warehouses.

The continuous monitoring gives Walmart better visibility across the whole supply chain. As a result, the company can prevent stockouts, reduce unwanted wastage, and sooner restock products.

Amazon: Speeding Up Deliveries with Robots

Where warehouse effectiveness is in question, Amazon has stepped a step further by using robots and automation.

In its warehouses, there are thousands of robots that move products at a high speed, enabling the preparation of customer orders and shipping in a shorter time.

Automation not only speeds up deliveries but also helps minimize errors and multiply output, especially during high-demand times like Black Friday or holiday shopping seasons.

DHL: Delivering Faster with Advanced Data

DHL, a global leader in the logistics sector, has employed advanced data analytics to make its delivery process quicker and cheaper. With the processing of traffic flow data, fuel consumption, and delivery time, DHL is able to develop better routes, cutting down on costs and time.

This allows the company to deliver packages more accurately and less often late. With data as a primary tool, DHL has optimized its logistics processes and made its supply chain more dependable.

Future Trends in Global Supply Chain Technology

As supply chains grow more complicated and global, businesses are turning to new technologies to help them stay well-organized, adapt to disruptions, and adhere to rising demands.

First, newer forms of AI development will alter the manner in which supply chains function. With improvements in artificial intelligence and machine learning, they will allow businesses to automate more processes and make quicker, better decisions.

For example, companies will use AI to make live optimal routes by taking into account traffic, weather, and fuel usage.

On top of that, we will likely see more autonomous delivery vehicles, such as drones and self-driving trucks, which will make deliveries even faster and more trustworthy by diminishing human error.

At the same time, sustainability will become more important as companies look for ways to lower their impact on the environment. Technology will help them achieve this by making their supply chains greener and more sensible. As a result, supply chains will be both eco-friendlier and more cost-effective.