What Is Modern CMMS Software? A Comprehensive Guide for Facility Management

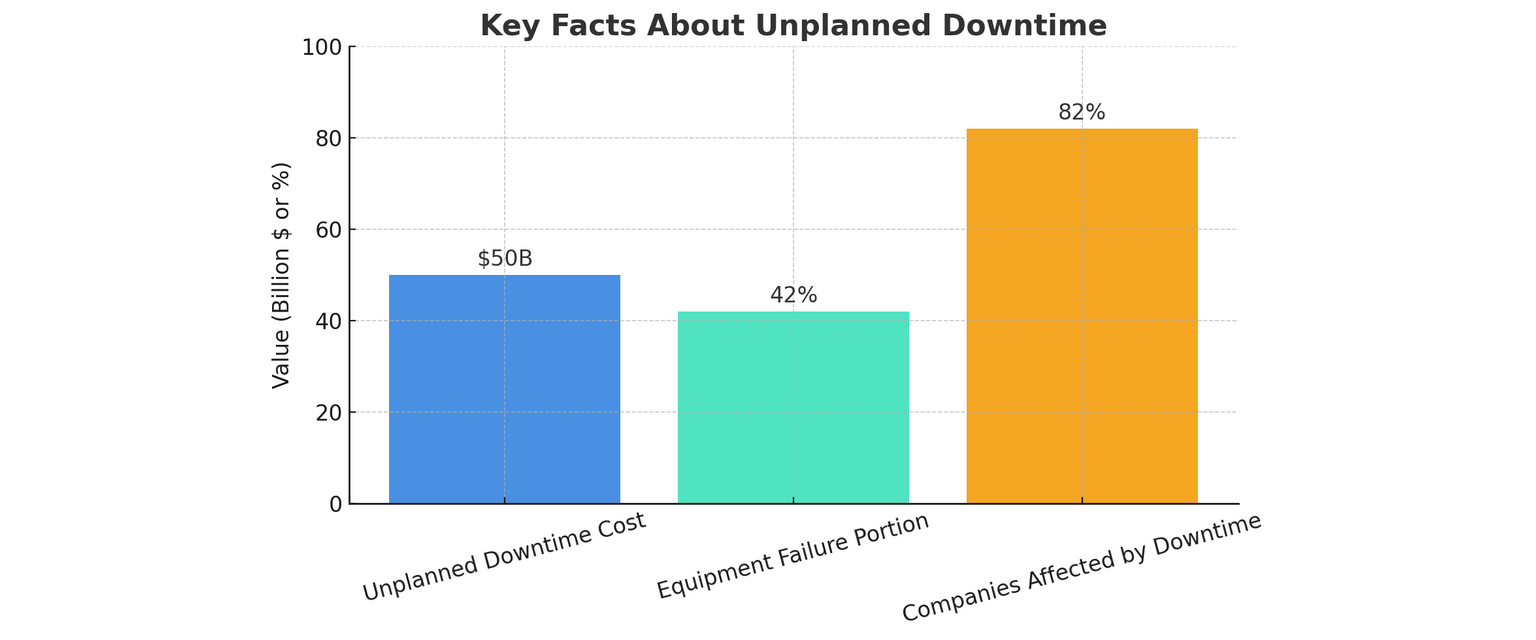

Did you know that unplanned downtime costs businesses up to $50 billion per year? And that equipment failure accounts for 42% of unplanned downtime expenses?

What’s even worse is that the problem of downtime is something that almost no company can avoid. In the last three years, for instance, around 82% of companies have suffered from at least one instance of unplanned downtime.

What Is a CMMS Software?

A Computerized Maintenance Management System, or CMMS, is a maintenance computer platform that aids organizations in scheduling, tracking, and optimizing maintenance activities.

It is utilized for preventive maintenance planning, generation of work orders, asset management and management of spare parts, and evaluation of asset performance over time.

Apart from facilities management, CMMS is widely used within industries whose equipment and facilities need maintenance on a regular basis, such as:

- Manufacturing – to maintain equipment in operation, prevent delays in production, and schedule preventive maintenance

- Logistics – to maintain equipment, vehicles, and warehouses

- Healthcare – to guarantee that medical devices are safe and accessible

- Energy and Utilities – to manage power plants, pipelines, and other core assets

Benefits of Using a Computerized Maintenance Management System (CMMS) for Facility Management

By and large, using today’s CMMS helps maintenance teams work more sensibly and keep equipment in better shape. But how?

One of the most significant benefits is the prevention of unplanned downtime. Forbes discovers that shutdowns take as much as 1%-10% of productive time available. Of course, these hours of nonproductivity are not recompensed but you must still bear the costs.

With predictive maintenance, scheduled tasks, and early warnings, however, teams can resolve problems before machines break, which means fewer surprises and less lost time.

Besides, CMMS can help save money. When companies can plan ahead, they avoid last-minute repairs and paying extra for emergency work. Plus, regular asset maintenance helps equipment last longer, so there’s no need to replace it as often.

Third, CMMS simplifies the work of specialized professionals. For example, technicians get clear instructions on their phones or tablets, so they know exactly what to do and where to go.

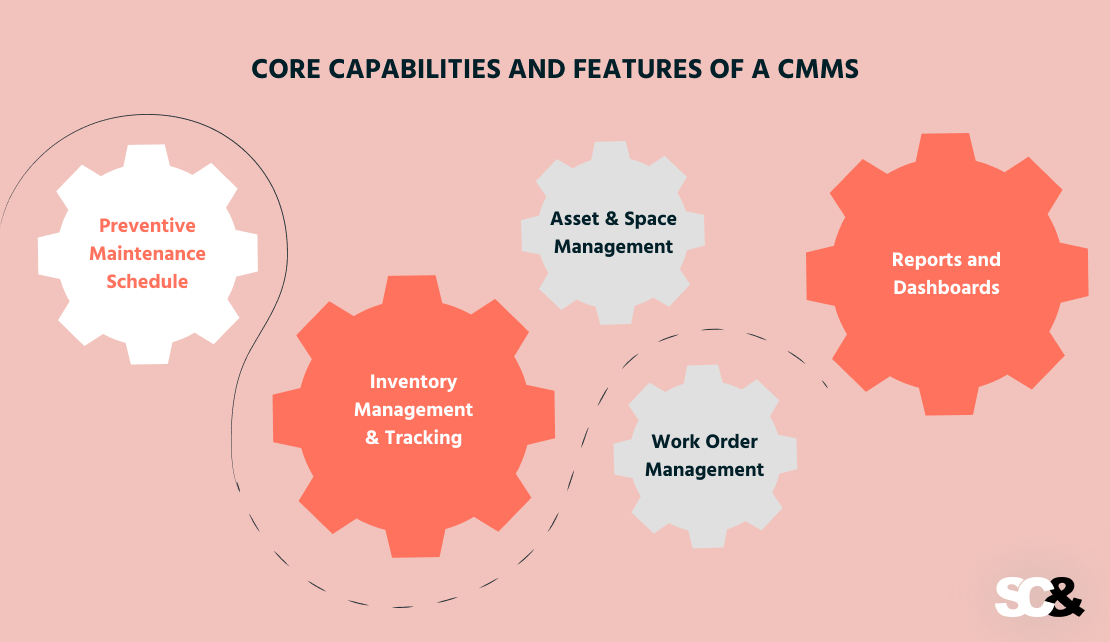

Core Capabilities and Features of a CMMS

For some, the term Computerized Maintenance Management System (CMMS) may appear a bit outdated, but the software actually comprises all the modern features to carry out repair and maintenance:

Preventive Maintenance Schedule

A modern CMMS allows companies to shift from the reactive maintenance method (repairing after it has failed) to proactiveness. Preventive maintenance features allow you to establish regular service intervals by time or use, and foresee equipment failures in advance.

Asset & Space Management

CMMS software provides one place to hold all your facility and equipment information: warranty and purchase information, maintenance history, user manuals, safety information, and tracking.

With agreeing asset records, departments can schedule maintenance service more rationally, watch repeat problems, and make adequate replacement or upgrade decisions.

Work Order Management

One of the essential functions of CMMS systems is observing maintenance operation through work orders. Users can quickly enter and track work orders, assign them to technicians, date them, and prioritize them.

Inventory Management & Tracking

Maintenance personnel and facility managers use spare parts and tools to get the job done, and a CMMS keeps it all in check. The system indicates what parts they have in stock, where they’re being stowed, and when they should be reordered.

Reports and Dashboards

Modern CMMS solutions are preloaded with built-in analytics that interpret raw maintenance data into usable, actionable information. They can be used to drive custom reports to support audits, track KPIs, and uncover improvement opportunities.

Key Criteria When Choosing a Modern Computerized Maintenance Management System (CMMS)

Choosing the right CMMS is a central decision that will affect daily operations, long-term fees, and team productivity. The most important criteria for choosing a system (apart from the components listed above) include:

- Cloud vs. on-premise

- Mobile readiness

- Integration requirements

- Total cost of ownership

- Vendor support and training

- Scalability and future-proofing

| Criteria | Why It Matters |

| Cloud vs. On-Premise | Cloud offers flexibility and easy updates; on-premise gives more control. |

| Mobile Readiness | Field teams can access tasks and log updates on the go. |

| Integration | Seamless connection with your current tools prevents data silos. |

| Total Cost of Ownership | Helps plan for all expenses beyond just the license fee. |

| Support & Training | Good vendor support speeds up adoption and troubleshooting. |

| Scalability | Ensures the CMMS grows with your business and tech needs. |

Why Is It Better to Opt for Custom CMMS Development

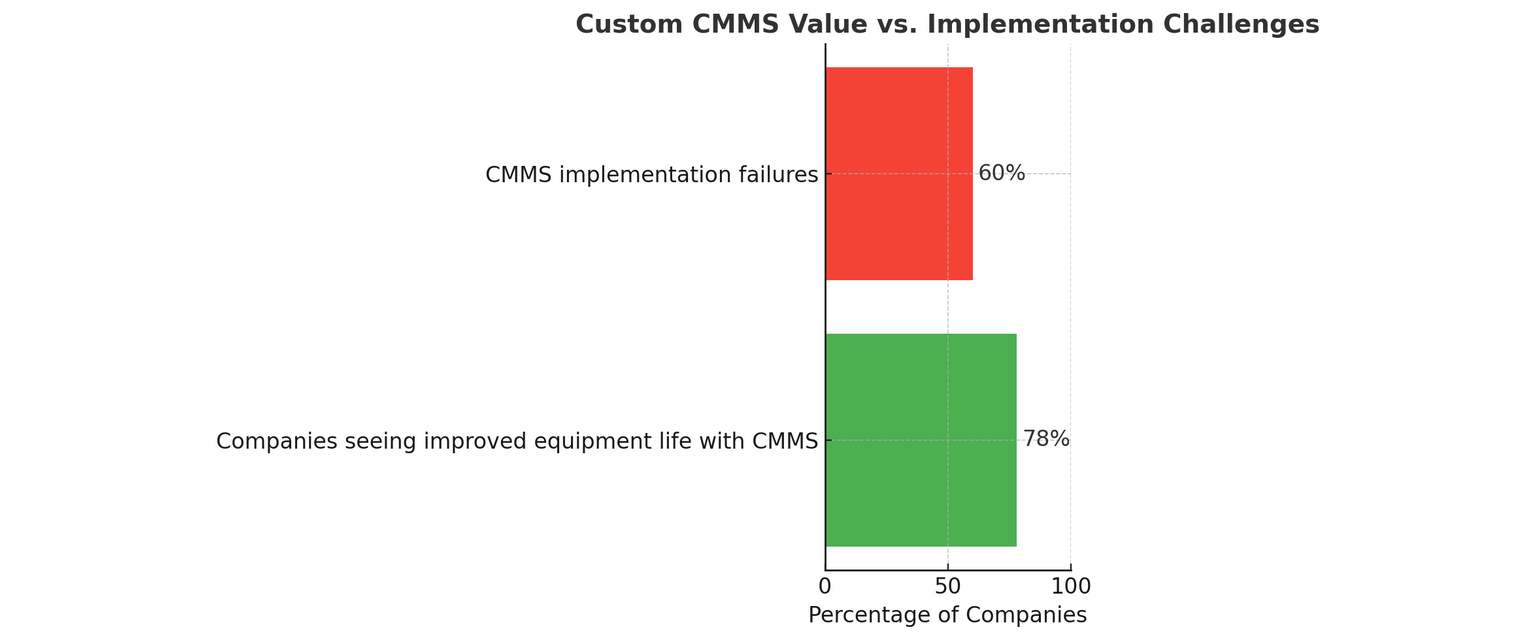

In 2017, it was estimated that 78% of companies using CMMS to manage their assets reported an improvement in the service life of their equipment.

However, it was also calculated that the majority of all CMMS implementation attempts fail. Why?

Companies often turn to market-ready solutions expecting a quick fix, but soon realize that these systems don’t serve their specific workflows, industry conditions, or long-term plans.

Prebuilt CMMS platforms are usually designed to serve the broadest possible audience, which means you may end up with features you don’t need and missing ones you do.

Trying to adjust your internal processes to fit the software, instead of the other way around, can lead to frustration and more chaos. Besides, many companies already rely on numerous platforms and systems for finance, inventory, HR, or production.

A market CMMS may not connect with them all, forcing manual data entry or creating data silos, which limits visibility and slows production down.

A custom Computerized Maintenance Management System (CMMS), in turn, is built to match how a company actually works, so it gets only the features it needs and nothing extra.

Modern Maintenance Management Software Implementation: Best Practices

To get the most out of a new CMMS, it helps to start with a vivid goal, for example, cutting downtime or supervising equipment in automatic mode.

Next, you should start preparing. Before starting, clean up your current data (such as asset lists and facility maintenance history) so every single detail is accurate and valid.

Then, try the system with just one team or location first. This way, you can see how it works and fix any flaws before rolling it out to everyone. Likewise, it’s also a good idea to start with an MVP to try out how in general the selected features get along with the corporate workflows and then expand the functionality.

Also, make sure your team knows how to use the system by giving them expansive training and support. After launch, it’s vital to supervise how the system behaves and make alterations as needed.

Here are four tips to bear in mind:

- Set clear goals

- Involve your team early

- Start small

- Offer helpful training

Also, pick a CMMS vendor that’s easy to work with and offers ongoing support. That way, your software can cope with any maintenance processes and keep working well in the long run.

At SCAND, we create custom CMMS software solutions for different industries such as manufacturing, healthcare, logistics, and facility management. With over 20 years of experience, we make sure your system is easy to use, works well with your tools, and gets the support it needs long-term.

Frequently Asked Questions (FAQs)

What’s the difference between CMMS and EAM (Enterprise Asset Management)?

A Computerized Maintenance Management System (CMMS) helps you manage maintenance tasks and keep equipment in good shape. EAM does more: it handles everything about your assets, such as buying, planning, and tracking maintenance costs. In simple terms, CMMS is a part of the bigger EAM system, centered around mainly on maintenance.

How much does custom Computerized Maintenance Management System (CMMS) development cost?

The price depends on how big your business is and what features you need. Custom CMMS usually costs more upfront than ready-made software but fits your needs better. This means you won’t pay for things you don’t use and can save money over time by working more efficiently.

What problems might come up when setting up a CMMS?

By and large, common problems include cleaning up old data, helping your team learn the new system, and connecting the CMMS with other software you use. Planning well and getting good training and support can help overcome these issues.

Can a CMMS work with other business software?

Yes! Many CMMS platforms can connect with programs for finance, purchasing, or equipment monitoring. Before you pick one, make sure it can link up easily with the tools you already use.